Drying

Hopper Dryer

Description

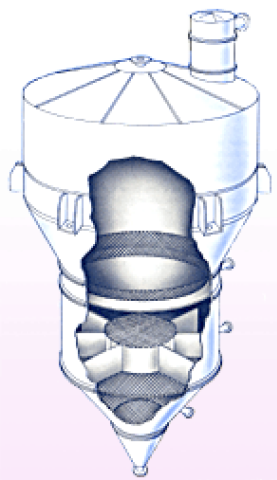

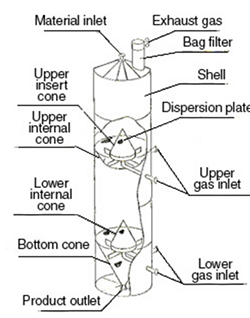

The dryer is direct heating type which brings heated air into direct contact with the raw materials. The dryer is composed of a cylindrical vertical body and conical bottom. Raw material is loaded into the dryer through the material supply port, fills the body, and gradually falls by gravity to the discharge port where it is discharged. Inside the upper part, an upper internal cone and an upper insert cone are installed, and inside the lower part, bottom cone and a lower insert cone are installed. These cones uniformly distribute the hot air necessary for drying. The insert cone functions are to rectify the mass-flow so as to achieve a piston-flow (a phenomenon that, in the filling bed, the material which is fed first is generally discharged first.

Features

- Long retention time

Since a long retention time is available, it is possible to dry in super-falling rate zone and remove unreacted monomers of resins or to solve odor problem when injection.

- Uniformity of product quality

By keeping the mass-flow and obtaining equal retention time, discharge of un-dried materials and quality deterioration by heat hysteresis can be prevented and uniform quality is obtainable.

- Easy switchover to different materials

As complete discharging is possible, switchover to different type of material is easily performed.

- Easy maintenance

No internal moving parts make maintenance easy.

Application

Polypropylene, Polyethylene, Polycarbonate, Polyacetal, EVOH.