Filtration

Horizontal Belt Filter

Structure and Principle

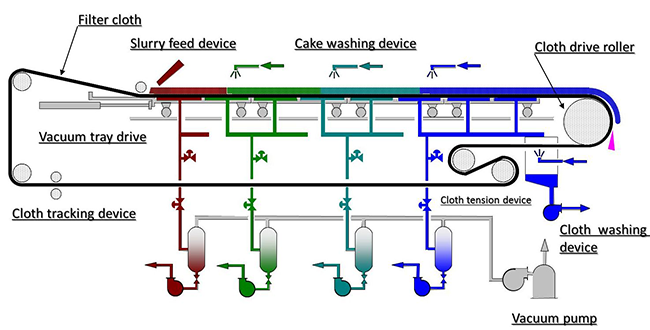

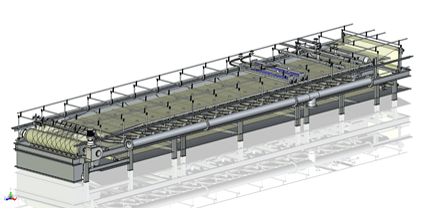

Horizontal belt filter is unique vacuum filter which is specialized in cake washing performance.

Effective cake washing is realized because the filter can replace uniformly mother liquor in wet cake by cake washing liquid. As uniform cake layer are formed continuously, uneven washing can be prevented.

Product cake after filtrated, washed and dehydrated is discharged continuously by means of cake discharge device. And filter cloth is washed continuously by means of cloth washing device in order to prevent clogging of the filter cloth.

Features

- High cake washing efficiency

As uniform cake layer are formed continuously, uneven washing can be prevented. Perfect cake washing is achieved by selecting optimum zone design of filtration, washing and dewatering to meet the specific needs. - Reduction of waste water treatment cost

Horizontal belt filter provides higher washing efficiency compared to conventional systems. This results in a significant reduction in the amount of washing liquid used.

By applying multi stage counter current cake washing system, further reduction of washing liquid can be achieved. - Complete product recovery

Product recovery loss can be minimized by cake discharge device.

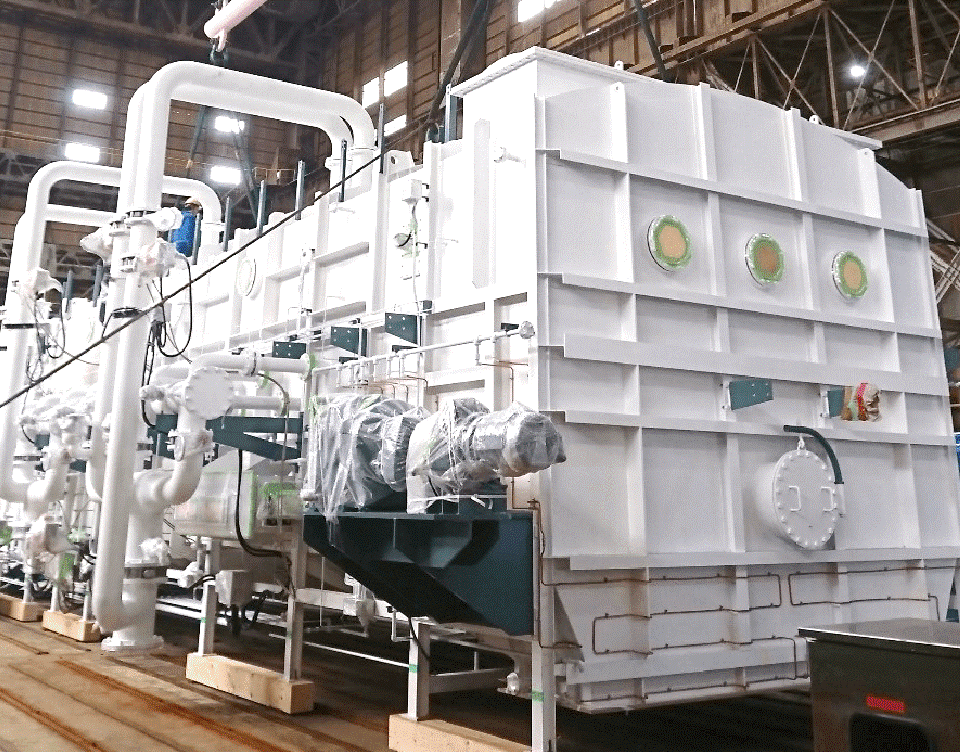

Filter cloth washing liquid is recycled as cake washing liquid. As a result, complete product recovery is achieved. - Gas tight construction

The main body can be simply covered with a hood or can be fully enclosed in a casing to provide stable handling of materials that include organic solvents.

Application

【Polymers】

ABS resin / MBS resin / PPS resin / Aramid polymer / Toner

【Organic chemicals】

BPA / Catalyst recovery in PTA

【Metal compounds】

Titanium oxide / Alumina / Aluminum hydroxide / Magnesium hydroxide / Raw material of secondary battery

【Others】

Activated carbon / Zeolite / Fly ash