Crystallization

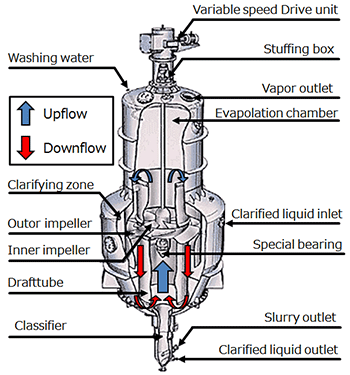

DP crystallizer

Structure and Principle

The DP(Double propeller) crystallizer was developed as improved model of DTB crystallizer. The crystallizer is equipped a fixed draft tube inside and double(inside and outside draft tube) propeller. The DP crystallizer generates up flow inside draft-tube and down flow outside draft-tube simultaneously by driven by one shaft, so this crystallizer can generate large volume of inner circulation, then can realize ideal mixing condition for industrial crystallization as low rotation speed and larger circulation.

Features

Large circulation volume

The crystallizer creates a favorable mixing condition so as to achieve uniform super saturation which prevent excess formation of crystal nuclei. Thus high quality crystal can be formed, and long period stable operation can be achieved due to minimizing scaling.

Sharp distribution of grain sizes

The crystallizer is enabled to change the circulation volume in crystallizer and adjust required operating supersaturation by adjusting revolution of double-propeller. In addition, double propeller with slow rotation speed strongly restricts generating secondary nucleation without decreasing circulation volume, so the crystallizer can manufacture crystals of required size, whether large or small in diameter, on a sharp grain size distribution.

Certainly scale-up

Operating super saturation is used as a scale-up factor, so reliable scale-up can be done easily.

Application

Applications

【Inorganic chemical】

Ammonium sulfate, Nickel sulfate, Peroxodisulfuric sodium, Alum, potassium chloride Barium chloride, Sodium nitrate, Soda ash, Silver nitrate , Sodium hydrogen carbonate , Potassium carbonate, Sodium Phosphate, Boric acid, etc.

【Organic chemical】

Bisphenol-A, Caprolactam, Acrylamide, Hydroquinone, Adipic acid, Ammonium adipic acid Fumaric acid, Trehalose, Aspartame, Amino acid, etc.