Filtration

BoCross® Filter

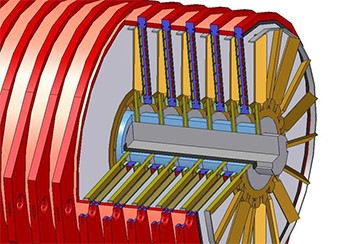

Structure and Principle

BoCross® using cross flow filtration technology is used in the pharmaceutical/food/pigment/cosmetic/electronic material industry, especially in the dehydration of calcium carbonate, silicon dioxide, barium titanate, etc., or in the filtration process of non-Newtonian fluids, Provides a complete solution.

For traditional/dead-end filtration, the pressure difference may increase by the increasing in the thickness of the filter cake and the blocking of the sieve pores by particles. In the end, the filtration cannot be performed. (The dehydration performance is not good or cannot reduce the moisture content)

BoCross® adopts the principle of cross flow filtration. The slurry flow direction is different that of the filtrate. There is no filter cake on the filter surface, and the sieve holes are not easy to be blocked.

Features

- Separable solid particle size range is 0.01-200μm

- It can handle high-viscosity materials; even 25,000 mPas materials can be processed at high flow rate.

- The final concentration is extremely high, up to 80 wt.-% or more.

- Absolute filtration: 100% solids can be separated from the filtrate.

- The whole filtration process is sealed without air contact.

- Can be operated continuously or intermittently.